Ultrasonic-Technology

Lock-Stitch-TechnologyChain-Stitch-TechnologyScissor-Cut-Technology

What is the ultrasonic-technology?

Ultrasonic as a means for cutting and welding is an old, well-known technology, but it requires a lot of experience.

The input of energy for heating the material occurs in the form of vibrations in a frequency range of 20 – 40 kHz.

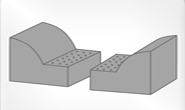

Cut- and weld-seam

The rotating sonotrode

Usually, sonotrodes in the form of a stamp are used for welding step-by-step, like high-frequency welding machines.

DAHMEN uses in collaboration with Jentschmann AG rotating sonotrodes with radial amplitude that allow continuous ultrasonic welding. With this technology a rotating sonotrode and an anvil roller turn simultaneously and welds the passing fabric between the two rollers. The sonotrode, vibrating with 35 kHz, applies the heat. This dynamic process requires an exact guiding and holding of the fabrics. The adjustments of the different welding parameters must be very precise and even regulated during the welding process. The development of a hardened, rotating steel sonotrode allows cutting and sealing of thick materials like carpets, conveyor belts etc. Until now, this was not possible with fixed cutting sonotrodes